CUSTOM BULKHEADS

Manufacturing bulkheads over 60 years

Trial and error for sixty years have provided us with what we believe to be the most economical yet structurally sound and pragmatic approach to bulkhead building. We've ammassed thousands of pages of notes and addendums to state and local codes all over the nation. If we are doing something different than a competitor, there's usually a reason.

Our systems come complete. No waiting for a box of parts from an outsourced company to assemble, merely drop the bulkhead on the floor and connect. These are a complete appliance outlet package designed for ease of installation, durability, and a clean, custom look.

We pride ourselves on our customer service, our efforts to extend business relationships, and our expedience to respond to any issues in the field.

Each unit built by Duncan Fabricating:

- Can be depreciated just as other laundry equipment

- Carries a serial number and can be financed

- Is factory tested and guaranteed against defects in materials and workmanship for one year

- Can usually be built and shipped within 10-15 working days of a firm order

“In three words I can sum up Duncan Fabricating: the best experience.”

— Brad F.

“John communicates so well and the quality of their bulkheads is excellent.”

— Scott S.

"Duncan Fabricating goes above and beyond to ensure customer satisfaction."

— John S.

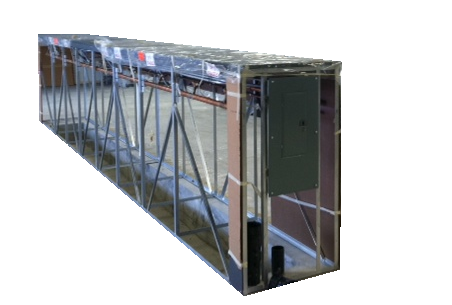

BULKHEAD FRAMES

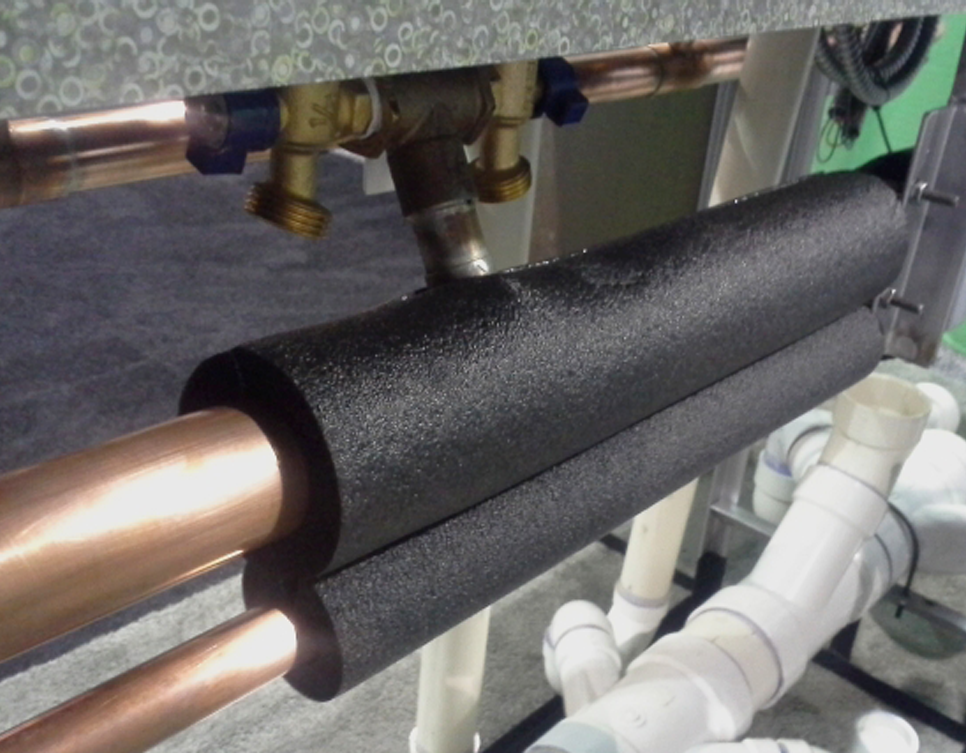

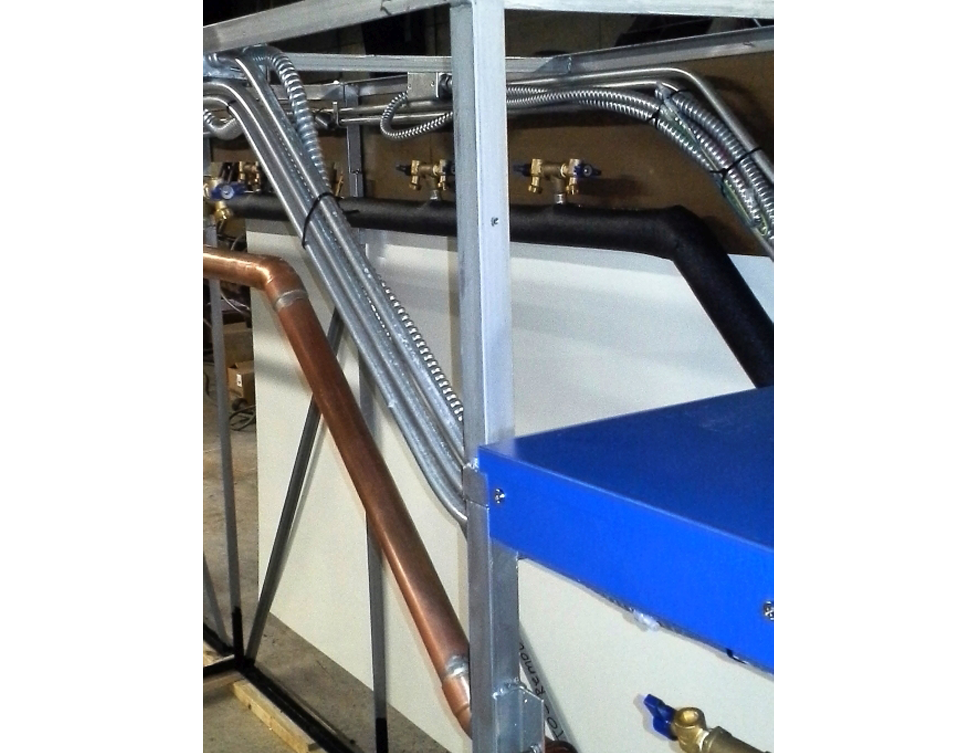

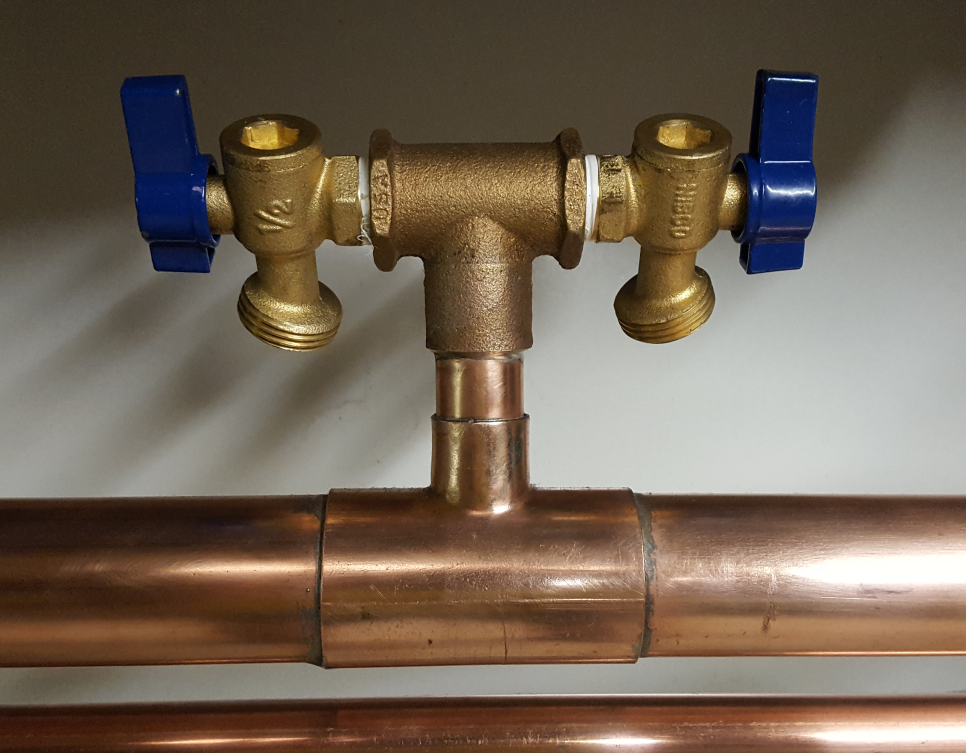

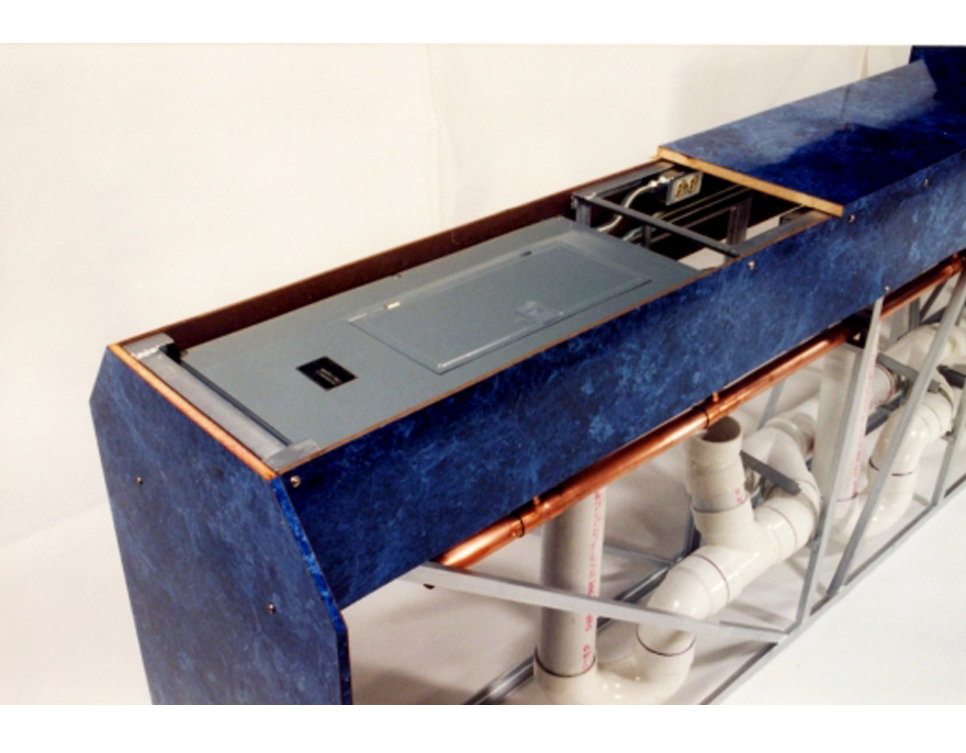

BULKHEAD WATERLINES

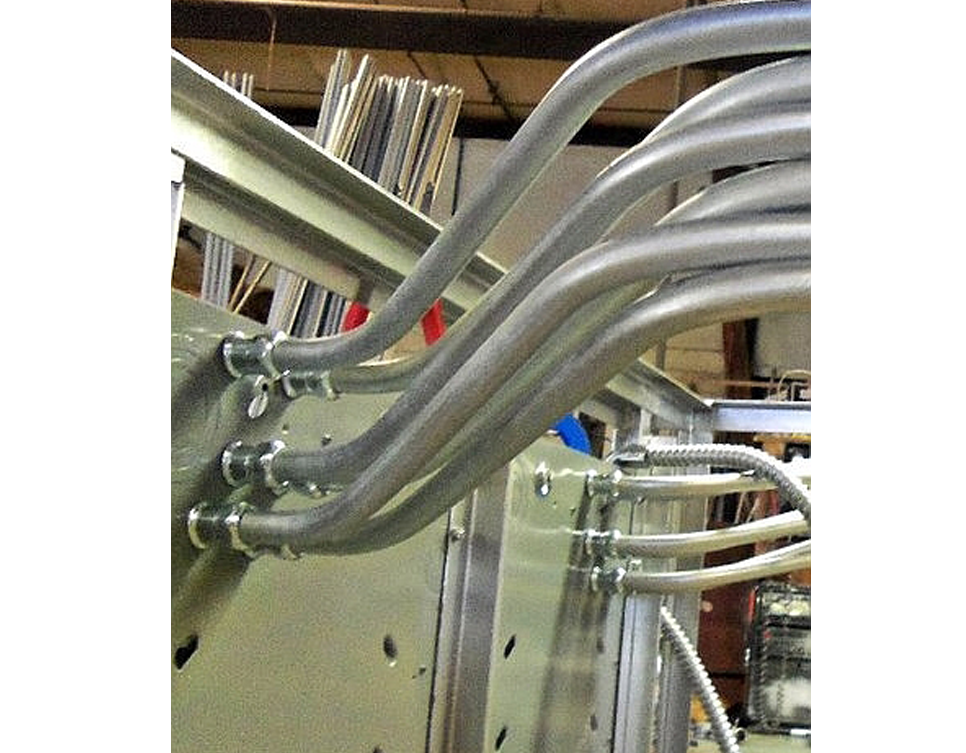

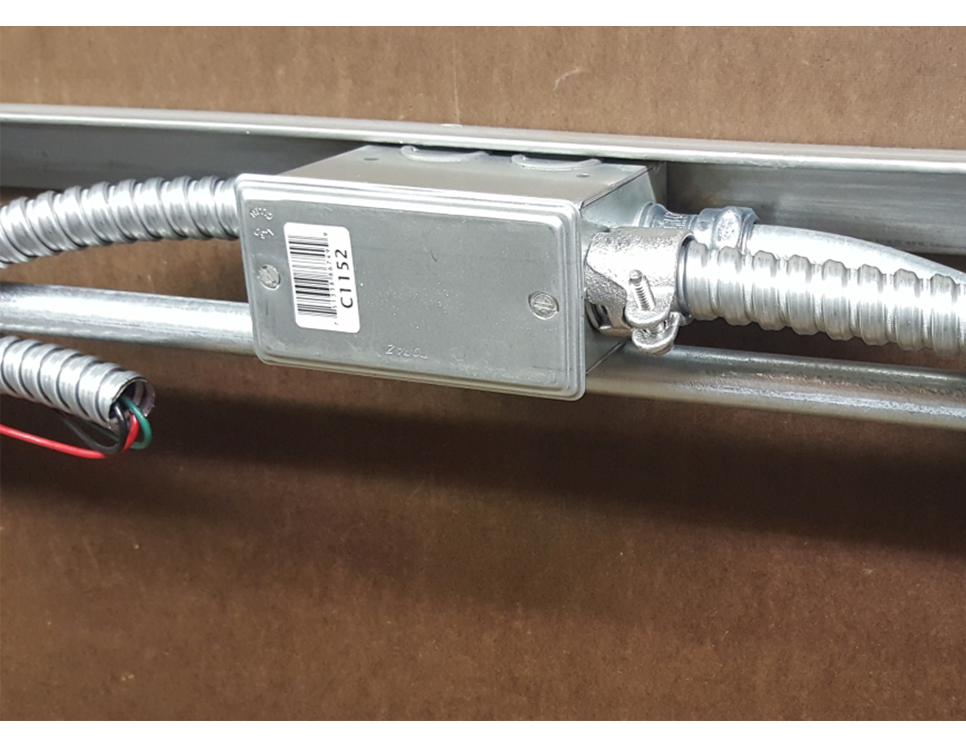

BULKHEAD ELECTRICAL

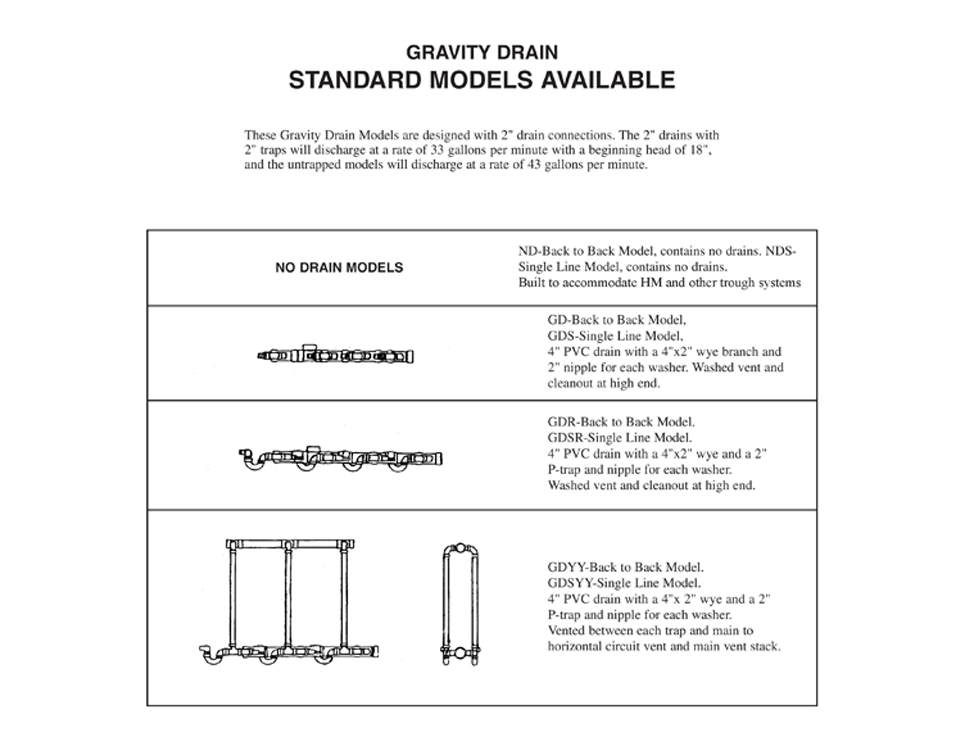

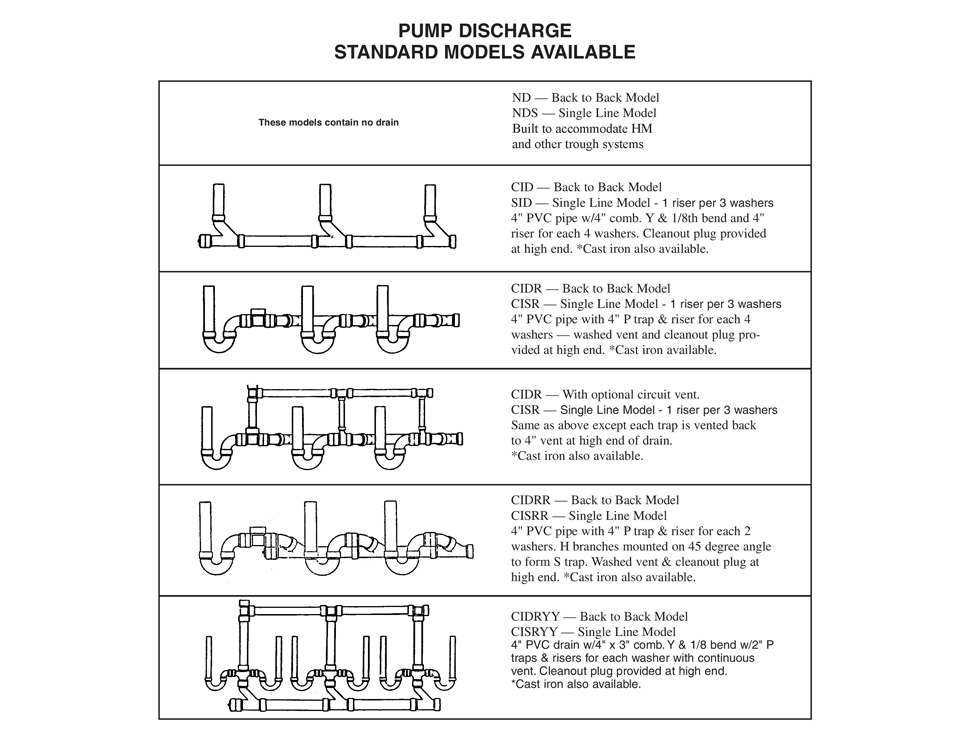

BULKHEAD DRAINS

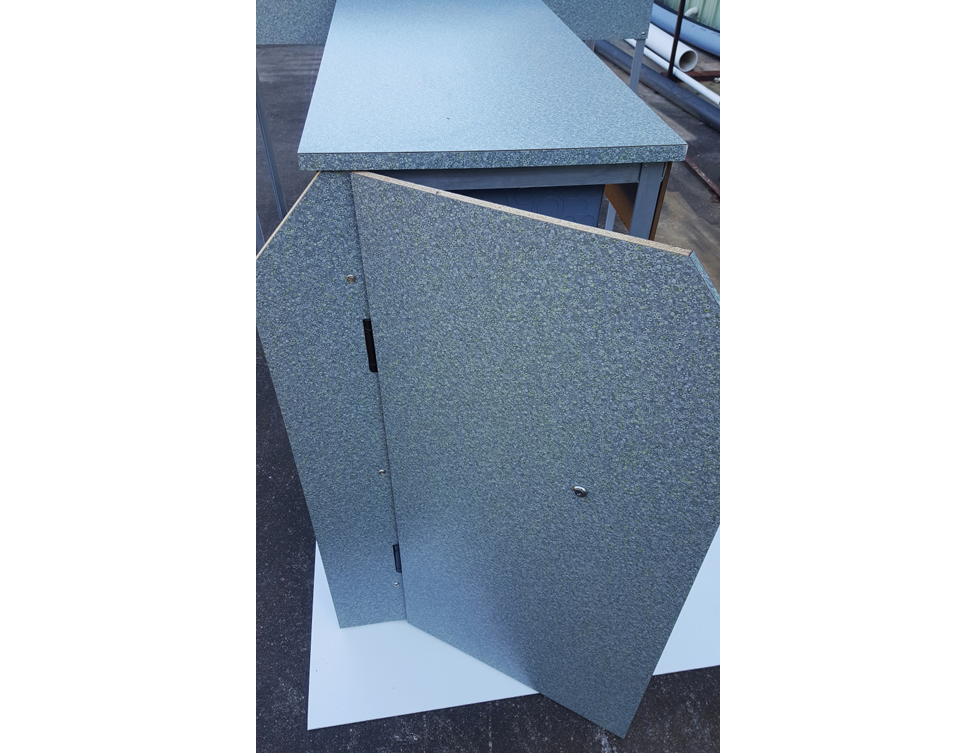

BULKHEAD COVERS

WHAT TO EXPECT FROM DUNCAN FABRICATING

With Duncan Fabricating, you are guaranteed to get a reliable bulkhead everytime. We provide you with a priced out estimate for your review & approval, prior to any work being started. With Duncan Fabricating, there are no surprises and we guarantee our work.

- 100% Satisfaction Every Time!

- Honesty – we always provide you a fair, up front price that won’t change.

- Professional design to help you make the best decision.

- Dependable – we’ll be there when you need us

- Commitment – we want you to be a satisfied customer and will work hard to accomplish this.

Call Duncan Fabricating at (205) 923-7777 to get your bulkhead started!